Dr. Ivan Poupyrev is part of Google’s secretive ATAP division, a team of Googlers tasked with making the stuff of science fiction reality. Take Project Jacquard, introduced by Poupyrev not at Google I/O’s 2015 keynote but rather at an under-the-radar standing-room-only session on the second day of the conference.

Project Jacquard won’t fly under the radar anymore. It was one of the most compelling things shown this year at I/O. And it’s closer to reality than you might expect thanks to a deal with Levi Strauss.

The goal was to design textiles that are not distinguishable from traditional textiles and that use the same manufacturing pipeline

Two things make Project Jacquard stand out from other pie-in-the-sky efforts from Google’s labs. First, Project Jacquard takes the same clothing you reach for everyday and transforms it into a wearable of its own. Second, Project Jacquard will (mostly) use existing manufacturing pipelines, requiring little tweaking to use the Google’s custom-designed, highly conductive yarns.

Google has created unique yarns using standard materials like linen, silk, cotton, and wool that are braided around a highly conductive material. These threads can be woven into garments, turning a specified area into a conductive surface that responds to your finger’s touch and recognize gestures. Google worked with a factory in Japan to produce the yarns and design the machines. The secret sauce of the yarns? Says Poupyrev, “That we own, and we’re not going to give it away.”

The yarns themselves are proprietary, but using them in clothing uses mostly existing manufacturing techniques, Google says.

The big trick, Poupyrev told us, was to get Project Jacquard to the point where the resulting fabrics could make it through the manufacturing process. “The goal was to design textiles that are not distinguishable from traditional textiles,” he explained, “and that use the same manufacturing pipeline for the yarns, textiles, everything, and [that you] can weave on any mill in the world. You still have to have some adjustment on programming machines, but you don’t have to adjust the process.” And that, he adds, is “the key to scalability, to turn it into mass production.”

Poupyrev’s team perfected a weaving structure that allows the conductive material to seamlessly become part of the fabric. “The top side can be anything you want; [the conductive area] could be invisible, visible, graphics, stretchable, anything. In the back, it’s woven together so you can connect electronics.” The idea, he notes, is to “design the connection technology once, and any electronics can connect to it. All the fashion designer has to do is use our design for the weaving control.”

Let’s be clear: Google claims no plans to make your next jacket or pair of jeans. The goal, says Poupyrev, is a much bigger vision of how a new breed of wearables can transform everyday garments. “We want to create an infrastructure, an ecosystem where the fashion designers and software designers can come together and work together…. So every software designer can become a fashion designer, and every fashion designer can become a software developer.”

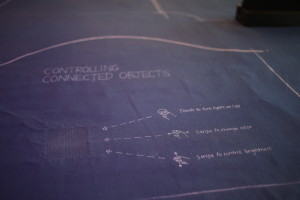

The technology was capably demonstrated at Google I/O, with all the wow! factor you can imagine for a bolt of cloth with sections of weave that are designed to control music playback and volume on a phone, or to adjust the brightness of the lights. But the electronics inside, paired with Bluetooth Low Energy connectivity, could go a lot farther than merely making subtle adjustments.

“Once we put the electronics there, everything that an activity monitors does, our garments will be able to do. Walking, motion, running, all of these. It’s simple, [the electronics are] super tiny, it’s just one extra chip and you’re done,” says Poupyrev, who expects the sensors to have their own language designed to facilitate interfacing between electronics and apps on your phone, for example.

Making the electronics waterproof is actually the easy part, according to Poupyrev. The harder part lies with making a sealed connection from the yarns to the electronics. “The water goes over the yarn using capillary reaction. So, connecting our yarns to electronics where it is sealed very tight, where the water doesn’t go by the capillaries through the yarns to the electronics was a hard, hard challenge. We solved it, so the water doesn’t go through the yarns, and it’s watertight and waterproof and we can wash and dry clean [the garment].

Lots of gotchas remain. What happens when you change jackets? Will you have situations where your controls or activity tracker are on your casual jacket, but not your business attire jacket? What happens in the summer months, when jackets have given way to 85 degree weather? When you change your clothes, will the sensors from one jacket be calibrated closely enough to seamlessly collect your data, without introducing errors?

We want to create an infrastructure, an ecosystem where the fashion designers and software designers can come together and work together…. So every software designer can become a fashion designer, and every fashion designer can become a software developer

Poupyrev envisions a world where you don’t need a universal, does-everything jacket. And he fully expects that developers and fashion designers both will come up with uses we haven’t envisioned yet. “Using your phone, you will be able to modify the functionality of your garment,” he gamely proclaims.

“People have been trying to make wearables functional, but I think the other way to go is to make fashion wearable,” Poupyrev says, pointing to the jacket he’s wearing as the prime example. “Don’t think about this as a technology you have to wear, think about it as the best linen jacket you can buy. My belief is that is the future of wearables.”

So when will all of this be available? “Our plans are very conservative,” admits Poupyrev. “By early next year we will try to move to the pilot production, [when] everything will be distributed to selected developers and designers. Hopefully by the end of the year [we can] scale up to production. We have to move fast. We don’t have time to sit down and think. It’s not blue sky, the blue sky phase ended a long time [ago]. We’re now pretty much in product: working with Levis, get stuff done, get it out, scale, manufacture, volume, wearability, testing, environmental regulations. It’s complex, but we believe the value is so high, it’s worthwhile to get it done.”